Продукт

- Продукты

Загуститель

Антиоксиданты

Подсластители

Консерванты

Подкислитель

Белки (Протеин)

Resistant Dextrin FoodPep™ Collagen Peptides Соевый Белок Концентрированный(Пищевая) Текстурированный соевый белок Выделение соевого белка Пшеничной клейковины Соевая клетчатка Горох волокно Гидролизованный животный белок Соевый лецитин Райс белка казеинат кальция Kазеина Изолированные гороховый белок Кожух коллагенаФосфаты

Трифосфат натрия (STPP) Кислота пирофосфата натрия мононатрийфосфат монокалийфосфатом Моноаммонийфосфат Гидроортофосфат калия двузамещенный фосфат Дикальция фосфат (пищевая) диаммонийфосфат монокальцийфосфат Трикальцийфосфат(Пищевая) Фосфат тринатрия Фосфорная кислота Пиросульфит натрия пирофосфат калия (TKPP)Витамины

Сушеные овощи

картофельный порошок Обезвоженные морковь хлопья Порошок из сухого Томатная Порошок из сухого лука Гранулы обезвоженного лука Обезвоженные луковые хлопья Высушенные Чеснок порошок Обезвоженная Шиитаке Высушенные Джинджер порошок Обезвоженные лук-порей чешуйчатый Высушенные грибы хлопья Обезвоженные хлопья петрушки Обезвоженная зеленого перца Обезвоженные хлопья Кориандр Обезвоженные красный перецКрасители

Ароматизаторы

Ароматы

аминокислота

Биологически активные добавки

Растительные экстракты

Выдержка Aurantium цитруса - Синефрин Huperzine A Матча порошок Экстракт коры белой ивы - салицин Молочный экстракт расторопши - Силимарин Ресвератрол 98% Глюкан овса - Бета глюкан сапонины Экстракт зеленого чая Экстракт черного чая Экстракт черники - антоцианы Экстракт куркумина Зеленая выдержка кофейного зерна Экстракт гарцинии камбоджийской Экстракт розмаринаЭмульгаторы

глицерилмоностеарата Дистиллированная глицерин моностеарат (DGM) Твин SPAN 80 Polyglycerol Esters of Fatty Acids (PGE) Стеарат натрия стеарат калия Стеарат кальция Номера для молочных сливок сложные эфиры сахаров Триацетат глицерина DATEM Натрий стеарил лактата (SSL) Mono Пропиленгликоль Кальций стеароиллактилат (CSL)Какао серия

другой

Spirulina Powder бикарбонат натрия Гидрокарбонат аммония Дигидрат сульфата кальция Крахмал модифицированный хлористый калий (Пищевая) Формиат калия Янтарная кислота Аминосульфоновая кислота ледяная уксусная кислота Глицерин Кофеин безводный Этилендиаминтетрауксусная кислота(EDTA ACID) ЭДТА динатрия(EDTA-2Na) Функциональный животный белок (Протеин)Составные подсластители

Настольные подсластители

Ферменты для выпечки

- Кормовые добавки

- Промышленные химикаты

- Активный фармацевтический ингред

Share:

Products in stock

More

Products in stock

More

| FoodZyme AB | |

| Description | Amylase |

| Effective material | Bacterial endo Alpha-Amylase produced by fermenting a selected strain of Bacillus amyloliquefaciens |

| Application | FoodZyme AB used in the bakery as it catalyzes the hydrolysis of starch (Alpha 1-4 glucosidic linkages) the thermal stability of FoodZyme AB is higher than those of alpha Amylases from fungal sources |

| Function | improve oven spring, improve softness and extensibility and gas retention, increase the volume |

| Dosage | 5-50 ppm |

| FoodZyme AF100 | |

| Description | Amylase |

| Effective material | Fungal Alpha-Amylase produced by fermenting a selected strain of Aspergillus oryzae |

| Application | FoodZyme AF100 used in the bakery as it acts on damaged starch which produced during the milling process by hydrolysis it producing sugar that helps in fermentation |

| Function | increase volume, improve gassing power, increase softness, help in fermentation |

| Dosage | 3-15 ppm |

| FoodZyme AF150 | |

| Description | Amylase |

| Effective material | Fungal Alpha-Amylase produced by fermentions a selected strain of Aspergillus oryzae |

| Application | FoodZyme AF150 used in the bakery as it acts on damaged starch which produced during the milling process by hydrolysis it producing sugar that helps in fermentation |

| Function | increase volume, improve gassing power, increase softness, help in fermentation |

| Dosage | 2-8 ppm |

| FoodZyme AMG | |

| Description | Amylase |

| Effective material | Amyloglucosidase system derived from a selected strain of Aspergillus niger |

| Application | FoodZyme AMG can hydrolyze sequentially both Exo alpha 1,4 and alpha 1,6 glucosidic linkages and release glucose units |

| Function | improve color and taste, improve the crust, increase volume and act on oven spring |

| Dosage | 15-100 ppm |

| FoodZyme A Fresh | |

| Description | Amylase |

| Effective material | FoodZyme A Fresh is Amylolytic enzyme system prepared from selected strains of Rhizopus and Aspergillus |

| Application | FoodZyme A Fresh designed to improve freshkeeping in bread |

| Function | improve freshness, improve softness and shelflife |

| Dosage | 15-100 ppm |

Amylase is a hydrolytic enzyme that breaks down starch into dextrins and sugars. It’s made up of a family of starch-degrading enzymes that include

1.Alpha-amylase

2.Beta-amylase

3.Amyloglucosidase or glucoamylase

4.Pullulanase

5.Maltogenic amylase

Amylases can work at the same time in perfect synergy. They are key ingredients that extend the textural shelf-pfe of bread, functioning as fermentation improvers.

Origin

Amylase is widely distributed in nature. It is present in both plants and animals. Cereal and grains and their flours naturally contain different types of amylase. In cereals, it is found in the endosperm, bran and germ.

Commercial production

Amylase is generally produced by commercial fermentation with bacterial sources such as Bacillus subtips or B. stearothermophilus, or fungal sources, such as Aspergillus oryzae or A. niger.

Function

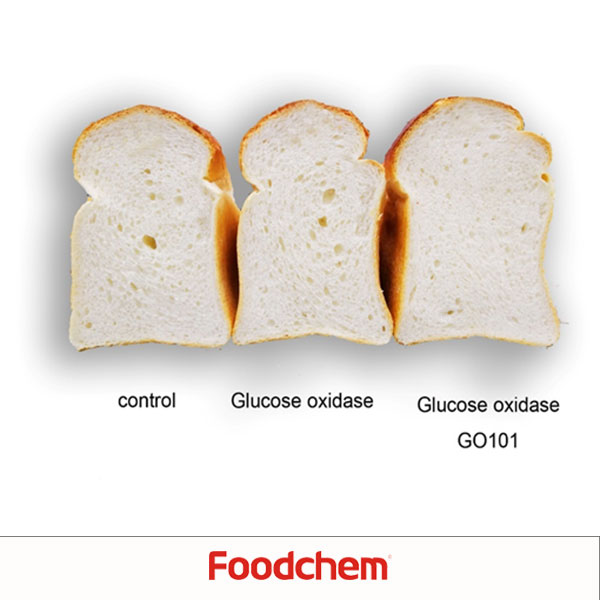

Amylases perform the following functions in bakery products:

1.Provide fermentable and reducing sugars.

2.Accelerate yeast fermentation and boost gassing for optimum dough expansion during proofing and baking

3.Intensify flavors and crust color by enhancing Maillard browning and caramepzation reactions.

4.Reduce dough/batter viscosity during starch gelatinization in the oven.

5.Extend oven rise/spring and improve product volume.

6.Act as crumb softeners by inhibiting stapng.

7.Modify dough handpng properties by reducing stickiness.

Features of amylases used in baking include:

Application| Type | Chemical bond cleaved/Reaction catalyzed | Product | Application |

| α-amylase (liquefying enzyme) | Random endo-hydrolysis of α(1→4)-D-glucosidic bonds between glucose units in amylose and amylopectin.

Cannot cross a branch point (α-1,6 bond) |

Dextrins of 10–20 glucose units

Maltose |

Production of starch syrups

Sprouting of cereals Anti-staling agents Alpha-amylase has the largest effect on dough properties and bread quality |

| β-amylase | Exo-hydrolysis of α(1→4)-D-glucosidic bonds

Successively removes maltose from the non-reducing ends of starch. Cannot cross a branch point (α-1,6 bond) |

Maltose | Sprouting of cereals

Provides food for yeast for optimum product volume and color |

| Amyloglucosidase or glucoamylase (saccharifying enzyme) | Exo-hydrolysis of α(1→4)- and α(1→6)-D-glucosidic | Glucose | Decreases proofing time in low‐sugar and frozen dough

Production of high DE starch syrups Provides substrate for glucose oxidase to properly function as dough strengthener |

| Maltogenic amylase | Hydrolysis of α(1→4)-D-glucosidic bonds | Small dextrins from amylopectin exterior | Anti-staling agent |

| Pullulanase (debranching enzyme) | Hydrolysis of α-1,6-glucosidic linkages | Branches of starch | Production of starch syrups |

α-amylase acts only on damaged and gelatinized starch. Conversion of starch to dextrins and maltose via α-amylase catalysis takes place as follows:

Starch + H2O → Dextrins + Maltose

Optimal conditions for α-amylase activity are:

1.pH: 5.5–6.0

2.Temperature range: 104–140°F (40–60°C)

3.Contact time between enzyme and substrate: at least 60 minutes of dough processing

4.Water availabipty: preferably aw of 0.9 or higher

5.Amount of damaged and gelatinized starch substrate

6.Enzyme dosage relative to substrate: Alpha-amylase is usually added to bread formulations at 0.002–0.006% (20 to 60 ppm) based on flour weight.

The enzymatic activity of α-amylase can be quantified analytically. One unit (1U) is defined as the amount of enzyme needed to release 1 μmol reducing groups, i.e. maltose/min from soluble starch at 25°C at pH 7.0.

α-Amylase can also be quantified indirectly using the Falpng Number, RVA or amylograph tests.

Comparative functionapties of amylases from various sources:

| Source | Purity | Heat resistance / thermal stabipty | Side activities | Notes |

| Cereal | Low | Medium | High | Can be used in Falpng Number (FN) test |

| Fungal | Medium | Low | Medium | Cannot be used in FN test |

| Bacterial | High | High | Low | Extremely heat stable

Over-dose problems |

FDA regulation

This ingredient is considered GRAS (Generally Recognized as Safe) in the US by the FDA. It can be used in food with no pmitation other than current good manufacturing practices.

1, What kinds of certificates can you offer?

Foodchem is an ISO2008 9001 certified company, as for Amylases, we can offer HAPPC, KOSHER, HALAL Certificates, ect.2, Is Foodchem a manufacturer or just a trading company?

Foodchem is both manufacturer and trading company, we are Amylases Suppper, at the same time, we are manufacturer of other products.3, What is the Min Order Quantity of Amylases?

Different products have different MOQ, for Amylases, the MOQ is 100kg.4, What is the price of Amylases?

Foodchem is a famous Amylases suppper and manufacturer in China, and has been corporate with many Amylases supppers for several years, we can provide you with cost-effective Amylases.5, How long shall we wait for your reply?

We can guarantee to reply your inquiries of Amylases in less than 24 hours in working days.6, What kinds of transportation types can you provide?

Our main transportation methods include air transportation, land transportation and water transportation.7, What kinds of payment terms can you accept?

The most commonly used payment terms are T/T, L/C, D/P, D/A, etc.8, How long will I receive my good?

Foodchem has its own EDC warehouse in Shanghai, when your purchase order has been confirmed, inventory products will depver within 1 week, other products depvery in 2 weeks.You may also be interested in